It Incorporates Robotics

Robotics has become an integral part of the PCB industry and made it for the better. Many companies use Pick and Place Machines for the assembly of PCBs. This is a type of industrial robot that uses an end-effector to grip and place components on a PCB. It has proven to be very accurate and fast, which is why it is used in so many factories today. PCBs are also inspected by robots. Optical inspection systems use cameras or lasers to inspect the solder joints and other features of a PCB. If there is a defect, the robot will mark it with a laser or stamp. This helps speed up the manufacturing process and results in higher quality products. In addition to incorporating robotics into the manufacturing process, some companies are now using them for product testing. Robotics can be used to test the functionality of a PCB as well as its durability. PCB technology continues to improve and incorporating robotics is only going to make it better. It has proven to be very accurate and fast, which is why it is used in so many factories today. Optical inspection systems use cameras or lasers to inspect the solder joints and other features of a PCB. If there is a defect, the robot will mark it with a laser or stamp. This helps speed up the manufacturing process and results in higher quality products.

There Are Many Different Types

There’s a variety of different types of PCBs, each with its own benefits and drawbacks. Here are some of the most common ones:

Rigid PCBs: These boards are made from a single sheet of material, usually fiberglass or another rigid substrate. They’re strong and can handle high temperatures, but they’re also bulky and expensive to produce.Flexible PCBs: As the name suggests, these boards are flexible and can be bent to fit into tight spaces. They’re popular in wearable technology and medical devices, where durability is important but the size is limited. However, they’re also more fragile than rigid PCBs and can’t handle as high a temperature.Metal Core PCBs: These boards have a metal (usually aluminum) core, so they can handle a high temperature and have good thermal properties. They also provide electrical shielding, which is useful for circuits with many signals. However, metal cores are expensive to produce and not as flexible as other types of PCBs.Rigid/Flexible PCBs: These boards have both rigid and flexible components that allow them to be used in many different scenarios without requiring separate materials or layouts. For example, many consumer electronics products use this type of board because it’s durable but thin enough to fit into small devices like mobile phones which you use for a variety of reasons nowadays.

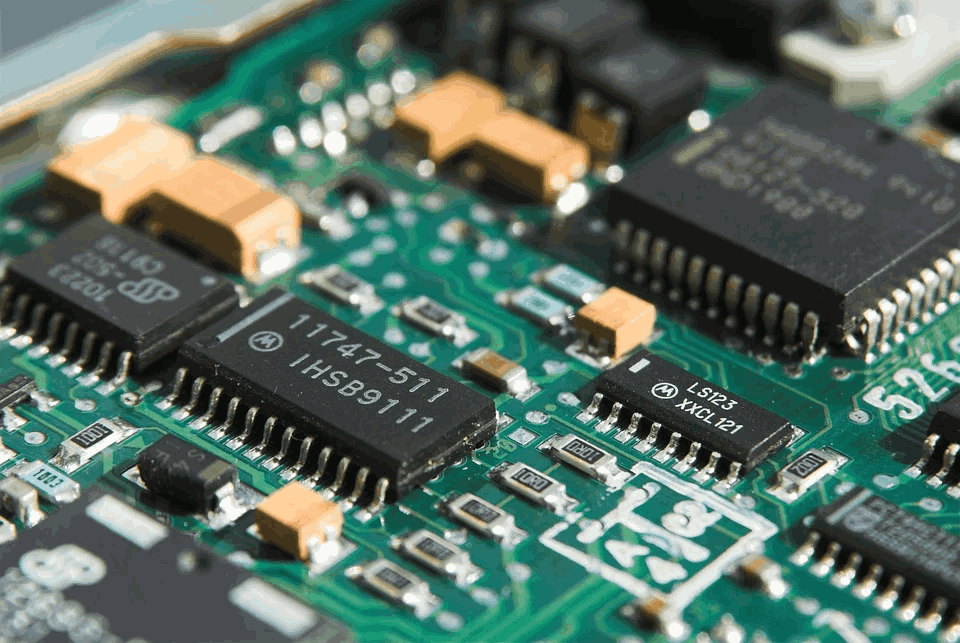

PCBs Are Found In A Variety Of Electronic Devices

There are tons of different types of electronic devices that we use in our daily lives. One thing you may not know about many of these is that they also contain printed circuit boards (PCBs) inside them, which can be found in everything from microwaves to cars and even home appliances like your refrigerator. If you didn’t already think there were a lot of things being made with PCBs around us, this will surprise you! Take the microwave for example. It’s probably something everyone has used at some point or another and most people have one in their own homes. Did you ever stop and wonder what exactly is powering all those buttons? A quick Google search will show that hybrid integrated circuits are being developed today for doing just that, powering up the display and all the buttons on microwaves. PCBs are also being used in other kitchen appliances like refrigerators and ovens. They’re even being put into cars now as well.

They Have Many Different Layers

PCBs contain different layers that all serve different purposes. The top layer is called the overlay, and it’s usually made of a transparent plastic film. This layer helps protect the circuit board and its components from physical damage. The next layer is the substrate, which is typically made of fiberglass or some other type of sturdy material. It provides structural support for the rest of the PCB and also serves as an electrical ground plane. Next are the copper layers, which are where most of the electrical activity takes place. There can be anywhere from one to dozens of these layers, depending on the complexity of the circuit board design. Finally, there are the solder masks and silkscreens. These layers help protect components from accidental solder bridges and ensure that the correct components are soldered in the right places.

The Manufacturing Requires Precision

The process of manufacturing PCBs is complex and requires precision. One of the manufacturing steps, referred to as “drilling,” can be particularly difficult for engineers because they must drill holes in precise locations on each PCB panel. One of the most important things that people don’t know about manufacturing is that it requires precision measurements and drilling processes require extreme accuracy when done by hand. Because humans are not perfectly precise when drilling, manufacturing engineers must use machinery to drill all the holes in a PCB.

It Has A Huge Role In The Electronics Industry

As you may have guessed, PCBs have a huge role in the electronics industry. Without PCBs, many of our favorite devices would not work as well or at all! They are used to create nearly every type of electronic device, from cell phones to laptops. Also, they allow for miniaturization, which is why they’re found in smaller devices. The low weight of PCBs and their resistance to vibration make them perfect for use in high-stress environments. PCBs can be designed to perform specific tasks, like carrying a signal or providing power. Everyone can benefit from PCBs, from everyday consumers to huge companies. PCB industry is so huge that incorporates robotics for a variety of reasons. There are many different types and can be found in a ton of devices you use every day. There’s a variety of layers proving that manufacturing requires precision and time. For all these reasons, PCBs have a big role in the electronics industry and making life better. You’re probably in touch with them every day without even knowing it!